Here I was, minding my own little hobby when all of a sudden – A wild mail appeared. A friendly invitation to review a PCB service. I would even be getting free mail 🙂

Well, would you look at that! I didn’t think that I would be noticed _AT ALL_ here in my little corner of the big internet. But then again I do tend to stick my head out from time to time when something interesting or funny comes my way.

So there I was – Free PCBs for a review posted on my blog. All of a sudden I had to take care of a lot of ethical questions. Would I even be able to make a fair review? Could I use free PCBs? Well, I would be lying if I said that I don’t have projects that only wait for a new boardspin so…. yeah, you guessed it – I took the offer.

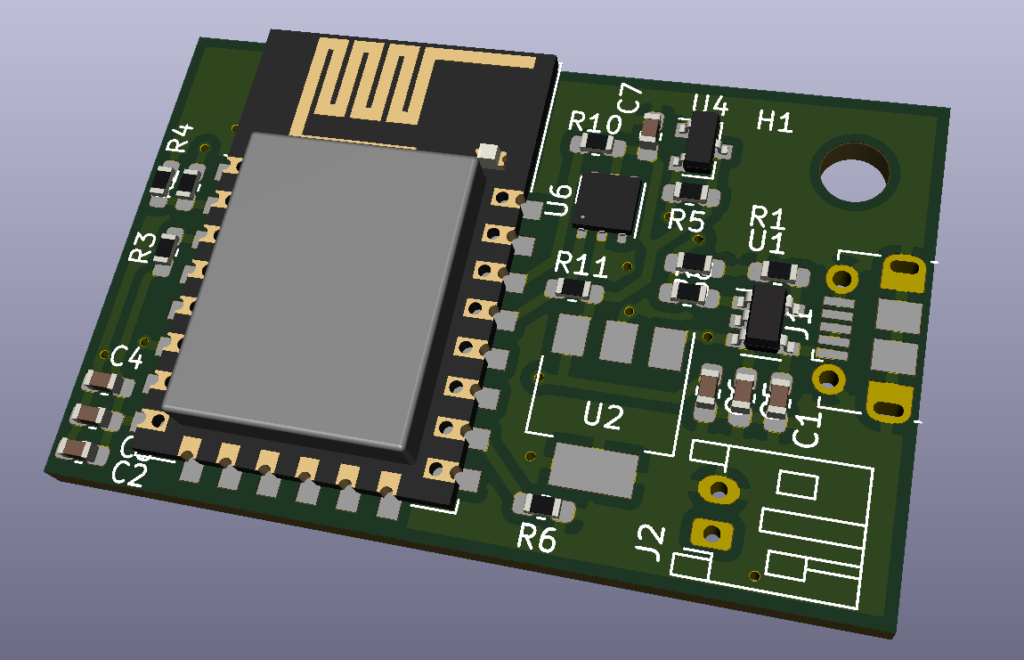

To make a long story short – And I am sorry Gloria, I am not the fastest man in this world. I ended up with a batch of PCBs for my WiFi Temperature/Humidity sensor project (Don’t worry if you haven’t heard a word about that yet – It will come eventually!)

In order to make my review I have broken it down into the following segments:

- Ordering

- Delivery

- Testing the product

- impression of PCBWay.com

- Summary

1. Ordering

The way it worked was this: I placed and order and prepared the files for review – when the review passed I would get enough credit put into my PCBWay account to order the batch. Complete with shipping and all.

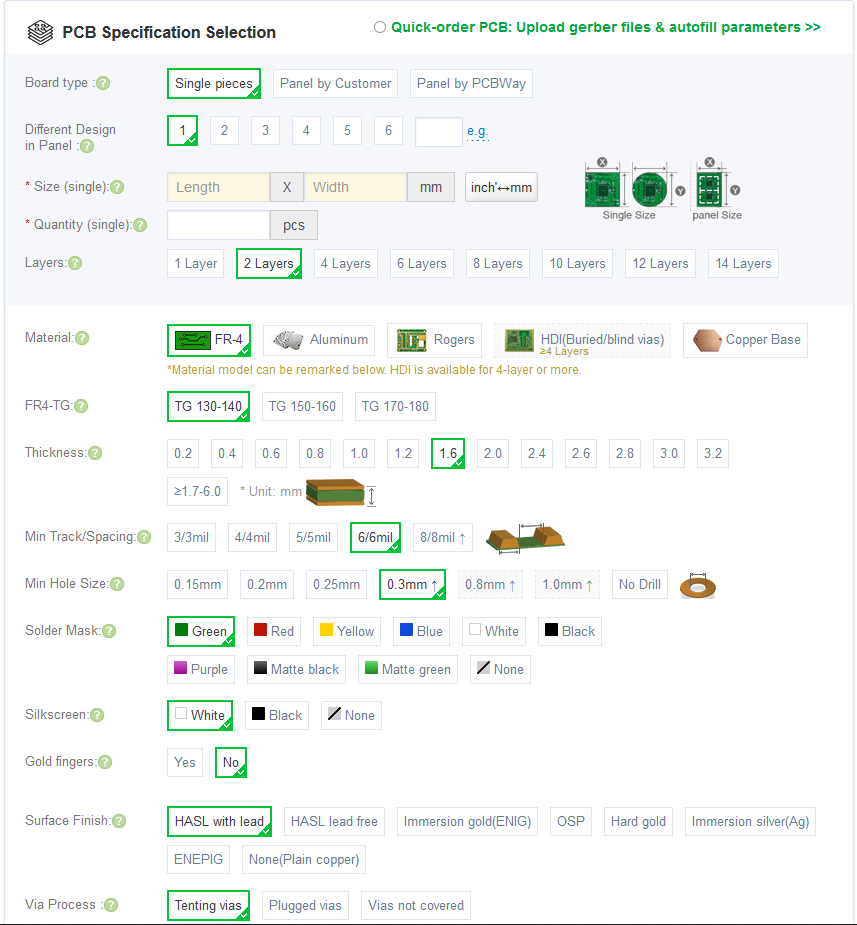

So I started by submitting my design. This is really straightforward – Just upload a Gerber package in a .Zip/.Rar file – I would say just as everybody else does. I chose the ‘PCB Instant quote’ which is the automated process for ordering ‘default’ PCBs. you know, stuff that doesn’t have any special requirements.

I will be honest with you – I am comparing PCBWay to JLCPCB. why? because they’re the one that I use otherwise.

It doesn’t take long before I notice that PCBWay offer quite a lot more options than JLC:

- Higher Tg temperatures available

- Thinner boards

- more colors in soldermask

- more surface finishes (Hard gold(!)) – even some that I don’t recognize

- Via processing. Wow, this is really nice!

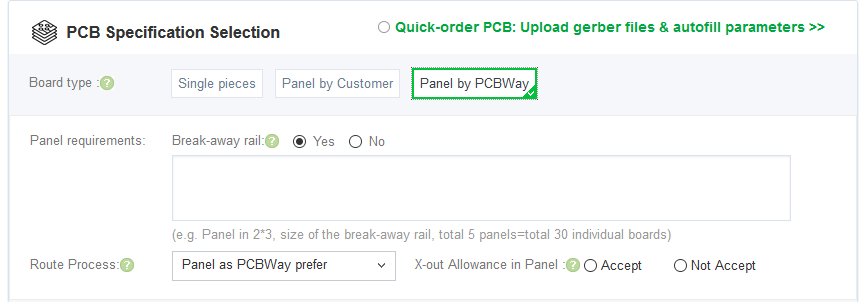

I decided to try out the panel feature. My design is quite small (about 40*25 mm). I chose ‘Panel by PCBWay’ as seen here:

What I apparently forgot was to ask for a panelization – I forgot to write ‘Please make my panel 2*4’ in the text field. What I THOUGHT was that PCBWay would automatically fill the maximum area with my boards (after all THAT would be nice, right!?)

Well – they didn’t. What I got you will see in a second. This is actually my only negative thing about the site. As for ordering PCBWay clearly have a LOT of option and a lot of those a hobbyist would never need. It is REALLY nice to have them though, and for more demanding projects PCBWay simply have a bit more ‘oomph’ compared to other companies within this line of work.

The pricing is a ‘normal’ 5$ for 10pcs which is really cheap!! There is not a lower price range for 5pcs (like JLC that does 5 for $2 – which is insane) The pricing is rising quickly if you change the ‘interesting’ parameters, like thickness, size, number of boards or delivery time. Just as you would expect.

Standard colors of soldermask and silkscreen is produced within 24 hours. other colors might take a bit longer (2-4 days) which makes sense when boards are pooled.

The shipping is, as usual, the most expensive part of the operation but that is just the way it is with this kind of services. I can still get a boardspin in less than a week which is incredible!

2. Delivery

Fast forward a week or so

The only downside? I had to pay import taxes to get my package. Not so free PCBs after all. And especially a bit begrudging because this project was a bit forced by the ‘free PCB’ offer. Well, at least I got a nice panel AND a framed stencil! – A good 80 sensor PCBs, right?

No.

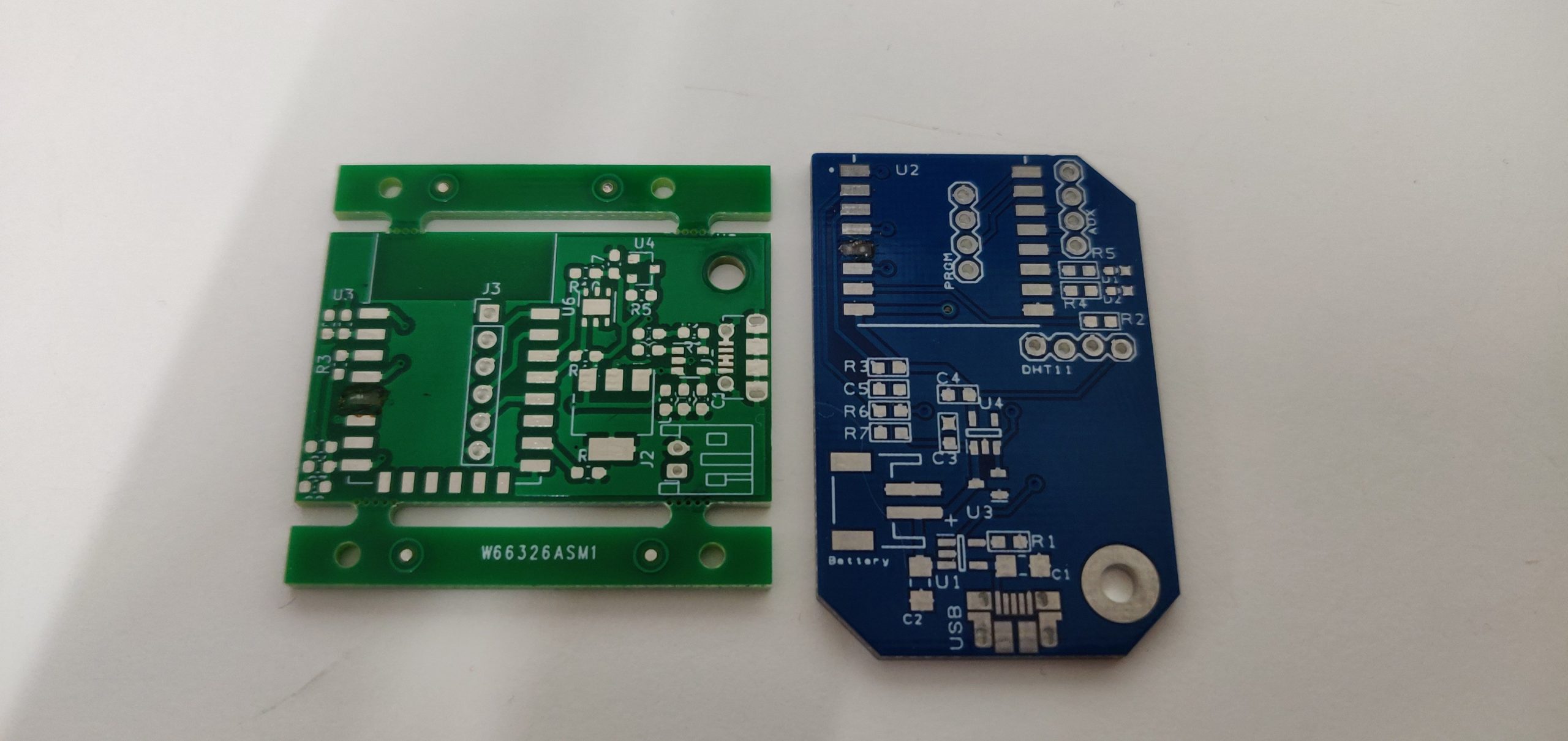

It didn’t take me very long to figure out that my panelization had gone wrong. This, my friends, are a 1*1 panel – with rails. Apart from the cuteness I was a bit angry about this. I don’t know if I should blame anybody else but myself but G** DA*** this was annoying! I did not get 10 panels of 8 – I got 10 ‘panels’ of 1.. missing 70 sensors here!!

Well – I did get a very polite answer from Gloria (Again, she’s very patient with my slow correspondance!) – I could get another go if I wanted. I’m not going to do that However, since it is not really necessary for this review. I can do the tests I want with boards I did get. And I think the error is on my anyway..

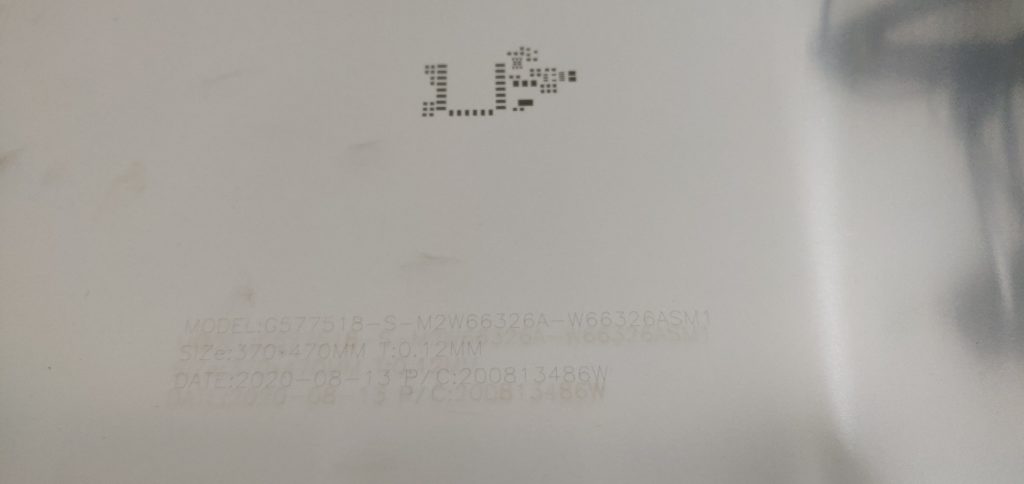

I did also get a stencil. I have made the decision to always get a stencil with my boards since I have a pick&place machine and if I ever end up in a situation where I need to populate a few boards I would use the stencil to apply solderpaste to my boards.

Apart from being ridiculous with the ‘1by1’ array I like the stencil. The frame makes it really sturdy and the file information is etched into the stencil itself. Not that I have that many frames to mistake it with (yet)

3. Testing the product

Initially I was dreaming of a strength-test. I have had some experience with delamination from other suppliers so this was something that i would really love to test. But how?

I ended up with a slightly less-than-scientific approach:

- heat a pad with solder for 10 seconds (350degrees)

- clean the pad with solderwick

- attach a wire with a normal soldering operation – trying to get it the same time on different brands of PCB

- Pull off the wire

I have done this – What I would have done was to measure the force applied to the pull (really the only way to measure this). this however, would require a larger setup so I have relied on my ability to sense how hard I was pulling the wire. I know – not very science-y

From my quick and dirty tests I conclude that the pads have a good adhesion even after a bit of thermal abuse. The pad did seem to lift slightly faster than other brands (and yes, the pad was of equal size and none of them was connected to anything else).

The boards are just Rev. 2 and Rev. 3 of my design. All in all they both have way better adhesion than I thought – A good thing! Maybe my soldering skills have just improved over the years 😉

4. Impression of PCBWay.com

I would like to address the website as a whole. My first impression was ‘Wow, that’s a lot of buttons’. From time to time there are some flashing banners that occupy a lot of the screen but when you manage to get through the ‘fluff’ you will see a very capable site.

The navigation is a but cumbersome but I attribute that to the gazillion features available. this makes the site harder to use but if you take the time to do it you will end up having a lot more options for ordering different styles of boards than other fab houses do. They even do Flex/Flex-Rigid boards! that is nice!

5. Summary

Would I use PCBWay for simple hobby projects?

Probably not. This is mainly because I don’t have a special need for the extra service they provide. And that is not entirely true. In the near future I might start playing with BGAs and THEN the features are important. Then I don’t know others that can do what PCBWay does.

Would I recommend PCBway to others?

Yes – they have a great service. Again I would use them for more exotic projects that require these special productions. I really should make something in Flex-rigid soon!

What is bad about PCBWay?

Mostly I am annoyed about the panelization thing. I’m still not completely sure that the thing I THINK I should do actually would get me a multi-panel of my board.

To sum up my experience with PCBWay.com:

A positive experience. I can recommend them.